Operating a 100 ton winch requires precision, skill, and adherence to safety protocols to ensure efficient and safe lifting and pulling of heavy loads. Whether used in construction, maritime, or industrial applications, mastering the operation of such a powerful tool is essential for completing tasks effectively while minimizing risks to personnel and equipment. In this guide, we explore the step-by-step process and best practices for operating a 100 ton winch, covering setup, safety precautions, operation techniques, and maintenance.

Pre-Operation Preparation

Before operating the 100 ton winch, conduct a thorough pre-operation inspection to ensure all components are in working order and the surrounding area is clear of obstructions. Follow these steps:

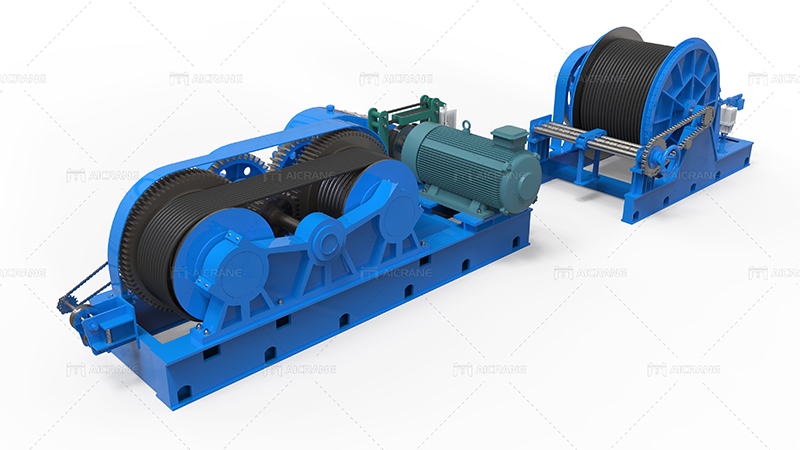

Check the condition of the winch: Inspect the winch, cables, hooks, and other components for signs of damage, wear, or corrosion. Verify that all safety devices, such as limit switches and emergency stop buttons, are functional.

Verify load capacity: Determine the weight of the load to be lifted or pulled and ensure it does not exceed the rated capacity of the heavy duty winch. Refer to the manufacturer’s specifications and load charts for guidance.

Secure the work area: Clear the work area of personnel and obstacles to prevent accidents or interference during operation. Establish barricades or warning signs to restrict access to the operating zone.

Review safety procedures: Familiarize yourself and your team with the winch’s operating manual, safety protocols, and emergency procedures. Ensure everyone understands their roles and responsibilities during operation.

Rigging and Setup

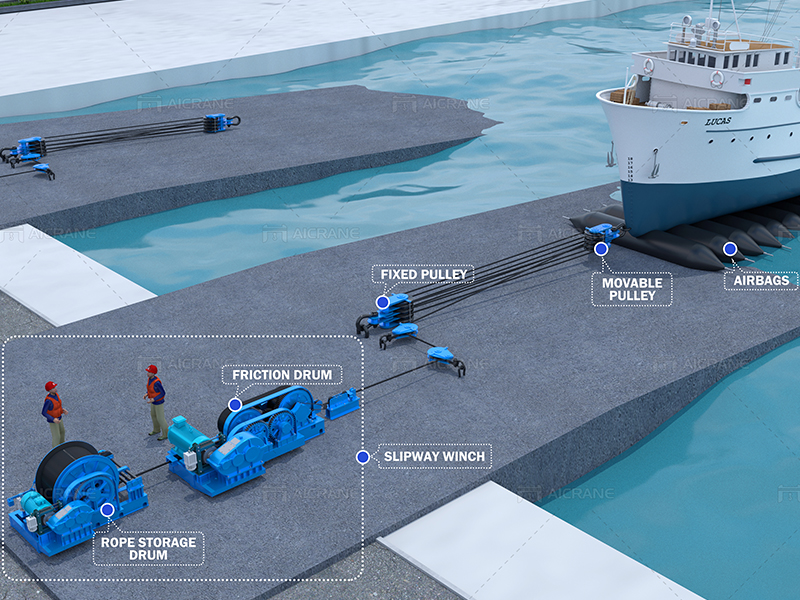

Proper rigging and setup are critical to the safe and efficient operation of the 100 ton winch. Follow these guidelin es:

Select appropriate rigging equipment: Choose the appropriate slings, shackles, and attachments based on the load characteristics, weight, and lifting points. Ensure all rigging equipment is in good condition and properly rated for the load.

Attach the load securely: Use suitable attachment points on the load and connect the rigging equipment to the winch’s drum or hook according to the manufacturer’s recommendations. Apply proper tension and secure all connections to prevent slippage or dislodgment during operation.

Check alignment: Position the winch and load in a straight line to minimize side loading and ensure smooth operation. Use guide rollers or sheaves to guide the cable onto the drum and prevent twisting or kinking.

Test the system: Conduct a preliminary test run of the winch to verify proper alignment, rigging, and operation. Lift the load slightly off the ground or apply tension to the cable to check for any issues or abnormalities.

Operating Techniques

Operating a 100 ton winch requires careful coordination, communication, and control to ensure safe and efficient handling of heavy loads. Follow these best practices:

Communicate effectively: Establish clear communication channels between the winch operator, signal person, and other personnel involved in the operation. Use standardized hand signals or radio communication to convey instructions and warnings.

Control speed and tension: Gradually apply tension to the cable and control the winch’s speed to prevent sudden movements or overloading. Use the winch’s controls, such as variable speed settings or torque limiters, to maintain precise control over the lifting or pulling process.

Monitor load movement: Keep a close eye on the load and surrounding environment during operation to detect any abnormalities or hazards. Stop the winch immediately if you notice any signs of instability, imbalance, or equipment malfunction.

Maintain situational awareness: Stay vigilant and aware of changing conditions, such as wind gusts, uneven terrain, or nearby obstacles, that may affect the operation. Adjust your approach and tactics accordingly to ensure safe and efficient lifting or pulling.

Follow load handling best practices: Lift or pull the load smoothly and steadily to minimize shock loading and reduce stress on the winch and rigging equipment. Avoid abrupt starts, stops, or changes in direction that could compromise safety or stability.

Implement safety measures: Enforce strict adherence to safety protocols, such as wearing appropriate personal protective equipment (PPE), maintaining a safe distance from moving parts, and using barriers or guards to prevent unauthorized access to the operating area.

Post-Operation Procedures

After completing the operation, follow these steps to safely shut down the winch and ensure proper maintenance and storage:

Lower the load: Gradually lower the load to the ground or designated resting position using the winch’s controls. Release tension from the cable and disengage any locking mechanisms or brakes to allow for safe unloading.

Inspect equipment: Conduct a post-operation inspection of the winch, cables, rigging equipment, and surrounding area for any signs of damage, wear, or hazards. Address any issues promptly and report them to the appropriate personnel for resolution.

Perform maintenance tasks: Follow the recommendations of winch manufacturer for routine maintenance tasks, such as lubricating moving parts, inspecting electrical connections, and cleaning debris or contaminants from the winch.

Secure the winch: Store the winch in a designated area away from moisture, extreme temperatures, and corrosive substances. Secure cables, hooks, and other accessories to prevent damage or loss during storage.

Operating a 100 ton winch requires a combination of technical expertise, situational awareness, and strict adherence to safety protocols. By following the steps outlined in this guide, operators can safely and efficiently handle heavy loads while minimizing risks to personnel and equipment. Remember to prioritize safety at all times, communicate effectively with your team, and perform regular maintenance to keep the winch in optimal working condition. With proper training, preparation, and execution, operators can master the operation of a 100 ton winch and achieve success in a wide range of lifting and pulling applications.